JAECO Scaffolding

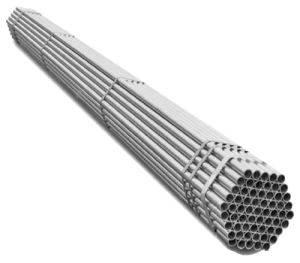

SCAFFOLDING TUBES:

GI TUBES SPECIFICATIONS

| Properties | BS 1139 SI | FPS |

|---|---|---|

| Wall thickness | 3.2 mm | 0.125 inch |

| Nominal OD | 48.3 mm | 1.901 inch |

| Sectional Area | 453 mm2 | 0.702 inch2 |

| Moment of Inertia | 0.115 x 10^6 mm4 | 0.28 inch4 |

| Section Modulus | 4797 mm3 | 0.29 inch3 |

| Radius of Gyration | 16.0 mm | 0.63 inch |

| Minimum Yield Stress | 320 N/mm2 | 46 ksi |

| Properties | BS 1139 SI | FPS |

|---|---|---|

| Wall thickness | 4 mm | 0.158 inch |

| Nominal OD | 48.3 mm | 1.901 inch |

| Sectional Area | 557 mm2 | 0.862 inch2 |

| Moment of Inertia | 0.1376 x 10^6 mm4 | 0.33 inch4 |

| Section Modulus | 5700 mm3 | 0.35 inch3 |

| Radius of Gyration | 15.7 mm | 0.62 inch |

| Minimum Yield Stress | 235N/mm2 | 34ksi |

| Properties | EN 10219 SI | FPS |

|---|---|---|

| Wall thickness | 3.2 mm | 0.125 inch |

| Nominal OD | 48.3 mm | 1.901 inch |

| Sectional Area | 453 mm2 | 0.702 inch2 |

| Moment of Inertia | 0.115 x 10^6 mm4 | 0.28 inch4 |

| Section Modulus | 4797 mm3 | 0.29 inch3 |

| Radius of Gyration | 16.0 mm | 0.63 inch |

| Minimum Yield Stress | 320 N/mm2 | 46 ksi |

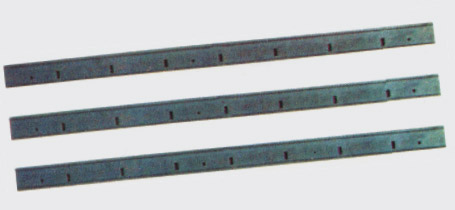

LVL SCAFFOLDING BOARDS (OSHA PROOF):

STEEL LADDERS:

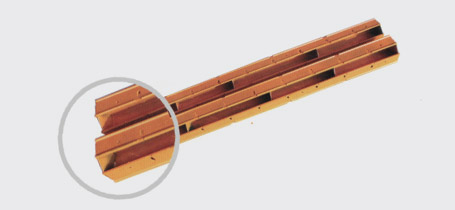

LADDER BEAMS AND LADDER SQUARE Ladder beams are made for a clear span between scaff olds. Its are constructed from high tensile steel and the saddles are welded at each joint for better security.

You can get a painted or galvanized fi nishing and available in diff erent lengths and weights.

| Available Sizes | |

|---|---|

| Thikness(mm) | Thikness(mm) |

| 3.0mm | |

| 6m | |

| 4m | |

| 3m | |

| 3.2mm | |

| 6m | |

| 4m | |

| 3m | |

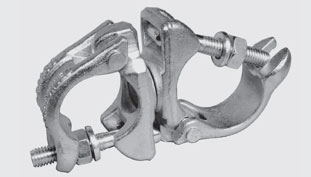

SCAFFOLDING FITTINGS:

- Weight – 0.965 kg

- Max. Slip Load – 15 KN

- Max. Distortion Load – 30 KN

- Finish – Zinc Plated

- Max. Displacement – 7 mm

- Fully conforms to standard EN 74

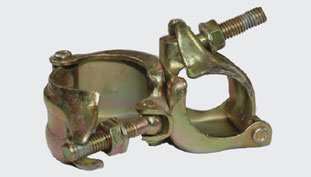

- Weight – 1.071 kg

- Max. Slip Load – 8.5 KN

- Max. Distortion Load – 17 KN

- Finish – Zinc Plated

- Max. Displacement – 7 mm

- Fully conforms to standard EN 74

- Weight – 0.570 kg

- Max. Slip Load – 12 KN

- Finish – Zinc Plated

- Fully conforms to BS 1139

- Weight – 1.42 kg

- Slip of Coupler along Section Load – 10 KN

- Slip of tube through Coupler – 6.5 KN

- Finish – Zinc Plated

- Hanging Load Vertically – 30 KN

- Always use in pairs

- Fully conforms to standard EN 74

- Weight – 1 kg

- Max. Slip Load – 6 KN

- Max. Bending Load – 19 KN

- Max. Displacement – 2 mm

- Finish – Zinc Plated

- Fully conforms to EN 74

- Weight – 820 g

- Max. Slip Load – 6 KN

- Max. Bending Load – 19 KN

- Fully conforms to standard EN 74

- Weight – 382 g

- Finish – Zinc Plated

- Fully conforms to standard EN 74

- The BRC is used with scaff olding in order to secure scaff olding boards. BRC ensures that scaff olding boards are carefully and safely locked in to the correct position for a safe work environment.

- Finish – Zinc Plated Fully

- Conforms to EN 74

- This is a unique safety product that enables a ladder to be fi rmly fastened by the stiles to the horizontal scaff old tubes or posts. These are always used in pairs.

- Fully conforms to standard EN 74

- Performs a similar function to the wedge clamps but recommended where forms are to be handled repeatedly or are likely to be subjected to considerable vibration.

- Fully conforms to standard EN 74

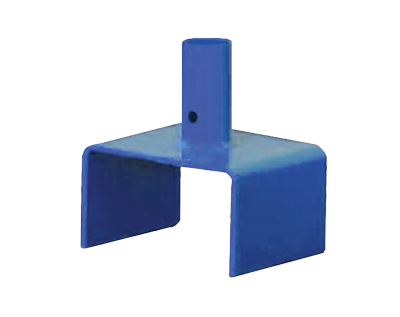

- Dimention: 48 x 48 mm

- weight: 690gm

- Finish: Pressed

- Dimention: 48 x 48 mm

- weight: 700gm

- Finish: Pressed

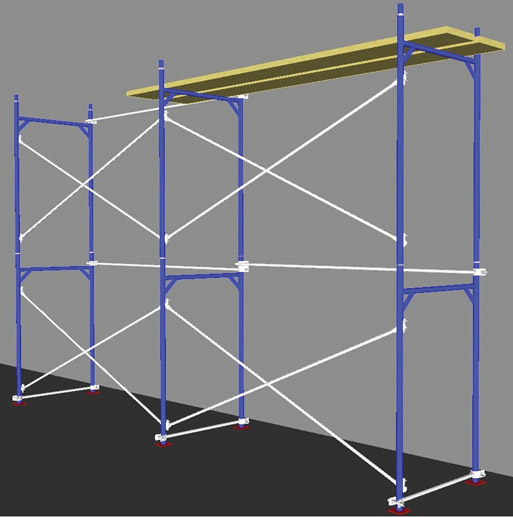

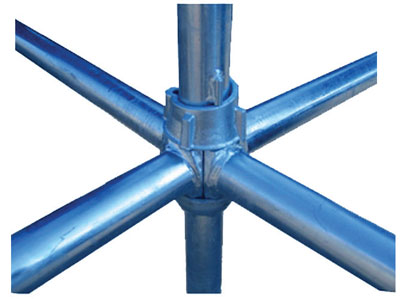

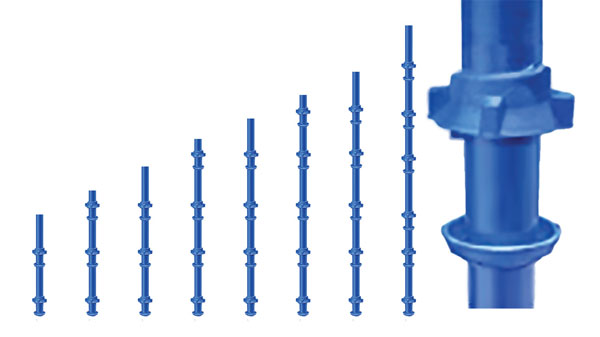

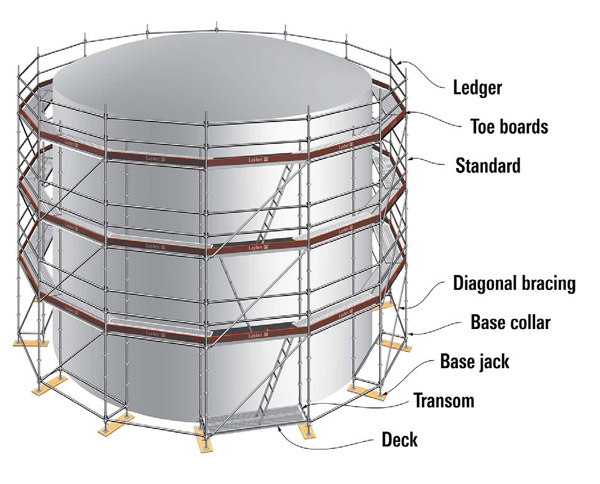

JAECO CUPLOCK SYSTEM:

- Strong – 40kN per leg.

- Saving in erection times, fast to assemble.

- Simple to erect.

- Systemized bracing reduces labour costs.

- Full Design support with C.A.D.

- Components up to 20% lighter than traditional counterparts.

- Versatile for Support and access.

- Confidence from in depth technical support.

The principal feature of JAECO Cup lock is the unique method of connecting ledgers and transoms to the standards in one single action without the use of nuts, bolts or wedges.

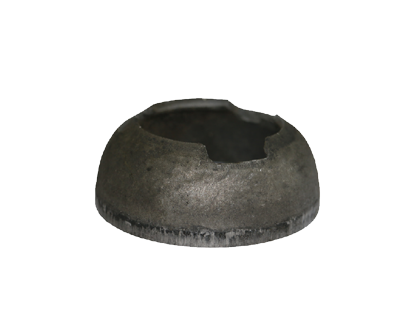

The Locking device is formed by two cups, a fixed lower cup which is welded to the standard at 0.5m intervals and a sliding upper cup. The forged blade ends of ledgers are located in the lower cup. The upper cup is moved down and rotated by hammer blows to give a positive and rigid connection.

It is this revolution node point locking principle which helps to make JAECO Cuplock faster to erect than other scaffolding systems. Since ledgers are located in node points on one level, setting out is easy and complete erection simplicity itself.

- Our experience of using cuplock in virtually every type of project in K.S.A enables us to offer you absolute confidence when using the system. Our extensive technical and design support includes an advanced computer aided design facility. With cuplock we provide simply the best technical support available.

Standards (Vertical posts) have top and bottom cups at every 500mm. They can be manufactured from 1.0m to 3.0m in length.

| Standards / Verticals | |

|---|---|

| Size (M) | Weight (Kg) |

| 3.0 | 13.70 |

| 2.5 | 11.40 |

| 2.3 | 11.10 |

| 2.0 | 9.25 |

| 1.8 | 8.55 |

| 1.5 | 6.85 |

| 1.3 | 6.35 |

| 1.0 | 4.55 |

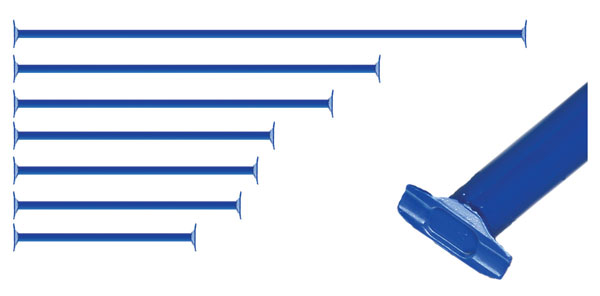

Ledgers are provided with forged blade ends to enable positive locking and are available in range of different sizes.

| Standards / Verticals | |

|---|---|

| Size (M) | Weight (Kg) |

| 2.50 | 9.0 |

| 2.0 | 7.35 |

| 1.80 | 6.40 |

| 1.60 | 5.65 |

| 1.30 | 4.70 |

| 1.20 | 4.25 |

| 1.0 | 3.65 |

| 0.90 | 3.20 |

| 0.90 | 2.35 |

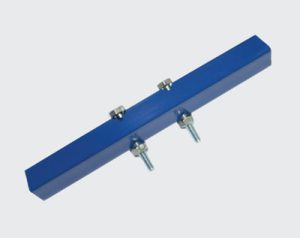

Intermediate Transoms provides board or bottom support where ever there is no ordinary transom present, i.e. between the standards.

| Standards / Verticals | |

|---|---|

| Size (M) | Weight (Kg) |

| 1.80 | 7.60 |

| 1.60 | 6.70 |

| 1.30 | 5.50 |

| 1.20 | 5.20 |

| 0.795 | 3.70 |

SCAFFOLDING ACCESSORIES:

- The Universal Jack can be connected at either end of the standard and used with the socket base or fork head. The threaded tube makes make height adjustments easy. It provides an adjustment option at either the top or the lowest end of scaff olding support structure.

The adjustable base jack can be used as an alternative to the universal jack and socket base. It fi ts underneath the standard and can be adjusted to accommodate diff erent surface levels. The base jack can be plated or painted.

The adjustable U-head can be connected at the top of the standard and has a U Head on top to support primary and secondary aluminium beams or decking beams for formworks.

The adjustable U-head can be connected at the top of the standard and has a U Head on top to support primary and secondary aluminium beams or decking beams for formworks.

Heavy duty wheel exclusively used with twist lock, Cuplock system. This can carry a static load of 800kg

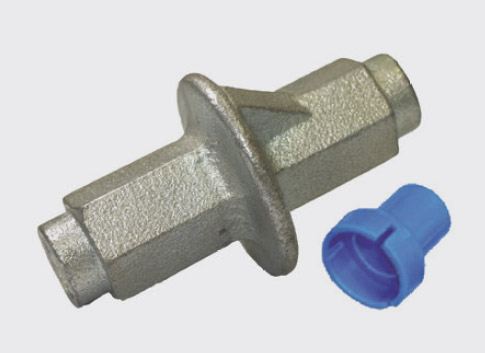

Spigots are used on the top of a standard to create an end to end connection with another standard. The spigots can be welded or be supplied loose with the nuts and the bolts, So they can be connected onto the top of the standard.

Spigots are used on the top of a standard to create an end to end connection with another standard. The spigots can be welded or be supplied loose with the nuts and the bolts, So they can be connected onto the top of the standard.

Cantilever Frames are used for providing support to decking or formwork at edges. The frame has ledger blades connected, So it can be fi tted onto cups of the standards. The frame can also accept jacks in three positions at the other end at 1.2m, 1.25m,and 1.3m from centerline of the standard.

Cantilever frames are designed with blade ends that can be easily located in the cup joint.

Beam Brackets are used to support the drop beams engaged within the regular slab support grid.

This eliminates the need for the beam bottoms to be propped up from the ground. The Beam Brackets are capable of receiving adjustable jacks and standards for reaching the beam bottom level. It has a safe load carrying capacity of 20KN.

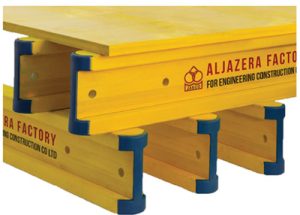

ALUMINIUM BEAMS:

Aluminium Beam is the product of careful research and development. It is indeed a most versatile shoring member covering the vast majority of building applications. The four beams currently available are designed to perform specifi c jobs for the most economical solutions. Other systems where only a single section is available, could result in compromises being made with regard to design that adversely aff ect labour and material costs and reduce profi ts in an ever competitive market place.

JAECO Aluminium Beams are ideal for use as primary and secondary members on soft formwork and equally suitable as walling on wall formwork in conjunction with JAECO’s robust Steel Soldier System. Provision is made at the top for a solid timber insert to allow plywood to be fi xed easily and ensures tighter joints for greater safety and speed on accuracy on site.

H-20 TIMBER BEAM

| Available Sizes | |

|---|---|

| Thikness(mm) | Sizes(m) |

| 4mm | |

| 6m | |

| 5m | |

| 4m | |

| 2m | |

| 3.2mm | |

| 6m | |

| 5m | |

| 4m | |

| 2m | |

| Available Sizes | |

|---|---|

| 5.9m | |

| 4.9m | |

| 3.9m | |

| 2.9m | |

F PROFILE UNIVERSAL PANEL FORMWORK SYSTEM:

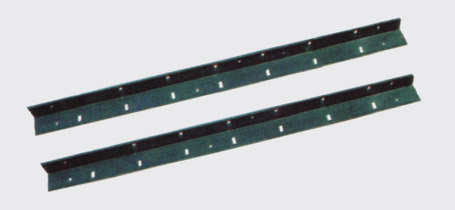

F Profile Steel Bar Frame Standard

Length:1200,1500,1600,1800,2400mm.

C Profile Steel Bar Used for Corner Frame

Length:1200,1500,1600,1800, 2400mm

F Profile Frame Ends

Length:583, 483, 433, 383, 283mm.

Any special sizes can be satisfied..

L Profile External Corner,63x63mm

Length:1200, 1500, 1800, 2100,2400mm.

Any special sizes can be satisfied.

F Profile Internal Formwork Corner

Length:900, 1200, 1500mm.

Any special sizes can be satisfied.

Support Steel Angle

Length:583, 483, 433, 383, 283mm.

Any special sizes can be satisfied.

F Profile Plywood Formwork Panel

Normal Length: 900, 1200, 1500, 1800mm.

Normal Width: 100, 150, 200, 250, 300, 350, 400, 450, 500, 550, 600mm.

GALVANIZED PROPS:

(Light Duty- 2.0 mm Inner & 2.0 mm Outer tube) JAECO props designed in keeping with British standards, these adjustable props/struts are of high grade steel. They are ideal for any type of construction requiring adjustable load bearing. Rough height adjustment is made possible by way of a heavy duty steel pin inserted into a slot in the outer tubular steel body through one of the best suited holes (in terms of off ering the approx. height extension) in the inner heavy duty tube. Precision adjustment of height is aff ected by a lever attached to a cast iron collar located just below the pin.

Inner Tube Dia: 48mm Outer Tube Dia:60mm .

(Versatile Light Weight Time Saving) Push-Pull Props are designed for use wherever an adjustable inclined strut is required. The push prop is generally used in the construction/erection of pre-cast units and plumbing of column and wall formwork. However, they are also suitable for other industrial applications.These Props are Available in a wide range of sizes.

WALL AND COLUMN FORMWORK SYSTEM:

Formwork with frame is made of steel and plywood as the board, it suits for any, horizontal structure.i.e. walls, columns, pillars, abutments and foundations.

AOLUTIONS AND PLANNING FOR FORMWORK

- Concrete surface fi nishing is the same smooth as plywood formwork.

- Steel frame formwork has longer lifetime than plywood.

- Can be recycle, reduce the waste and contamination to the environment.

- Save working time. Everything has been already made in the factory.

Columns Formworks

Heavy Duty Formworks

Columns Formworks

FILM FACED PLYWOOD

- Film: Dynea or Stora-Enso dark brown, black(Other color as request).

- Core: Poplar, Hardwood, Eucalyptus, Birch, Combi, Pine

- Glue: WBP (water-proof), MR, Melamine.

- Size: 1220x2440, 1250x2500, 1220x2500, 915x1830, 1500x3000, 1525x3050 (mm).

- Thickness: 6, 9, 12, 15, 18, 21, 24, 25, 27, 30, 35 (mm).

- Number of layers: 5-21 depending on thickness

- Moisture Content: 8-12%

| Density | |

|---|---|

| Item | Approx. kg/m3 |

| Poplar | 530 |

| Hardwood | 635 |

| Combined | 600 |

| Birch | 690 |

| Pine | 700 |

Formworks Accessories

Wing Nut

Waler Plate

Water Barrier Without Diss

Water Barrier With Disc

Tie Rod Dtwudag

Indian Tierod

Plastic Pipe

Plastic Cones

Rapid Clamp

C-CLAMP

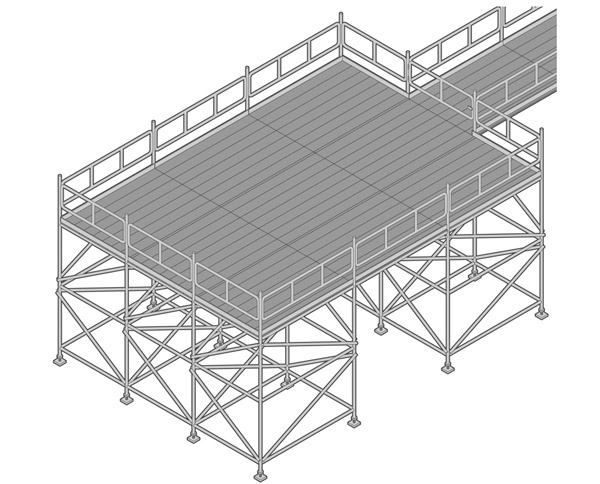

Applications of Scaffolding

Access Scaffolding

Mobile Tower Scaffolding

Independent Access Scaffolding

Slab/Beam Support with-H20